Freezing dough pieces

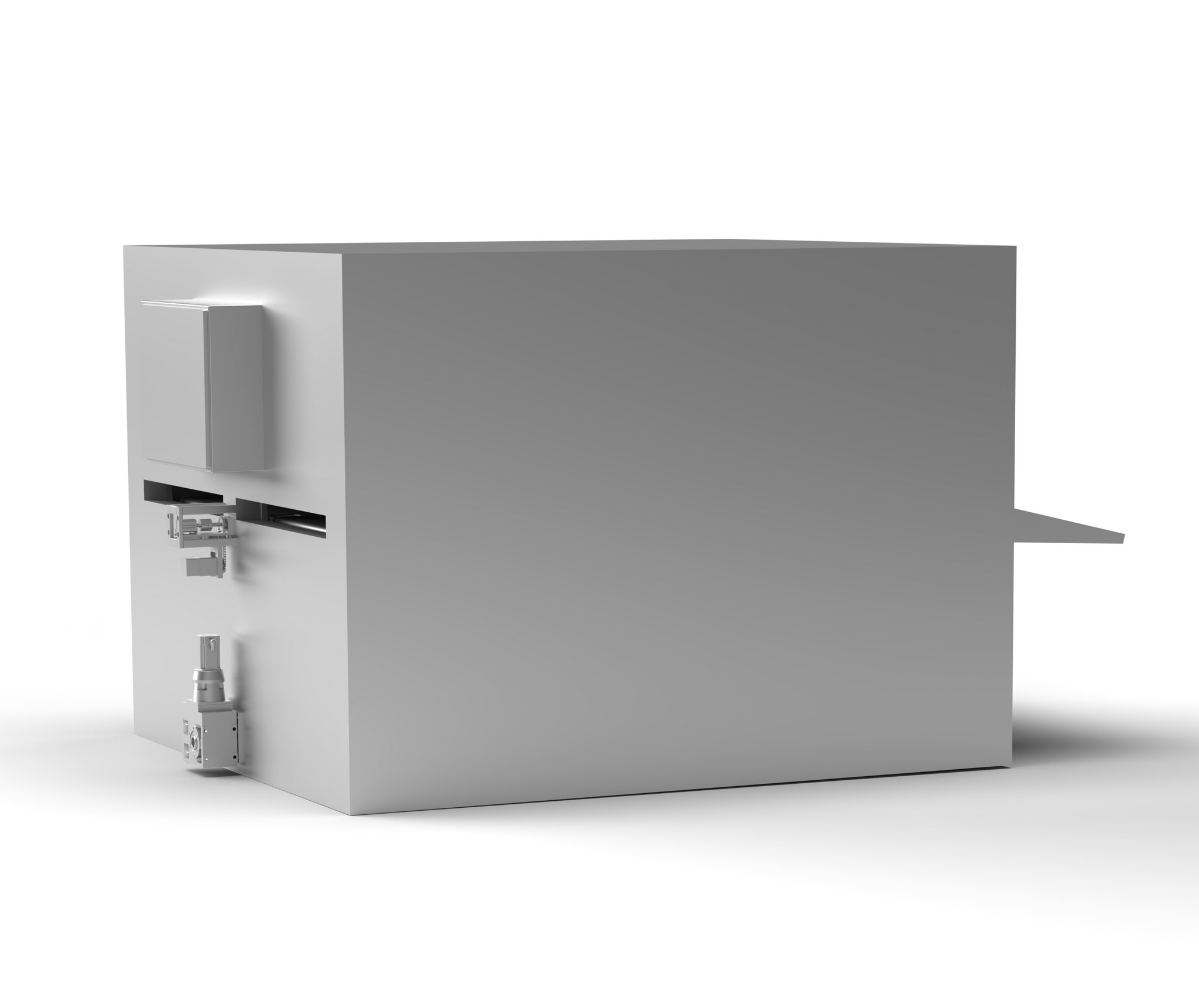

Eco-Froster

- Large freezing area in a small space

- Available from 21 m² freezer area up to your desired size

- Variable length and width possible

- Also known as "Piller" freezer

- Touch panel control for entering and saving parameters for different freezing programmes and remote maintenance option

- Automatic discharge after freezing

Energy and space-saving: the eco freezer for bakeries and bakery businesses from WP Riehle

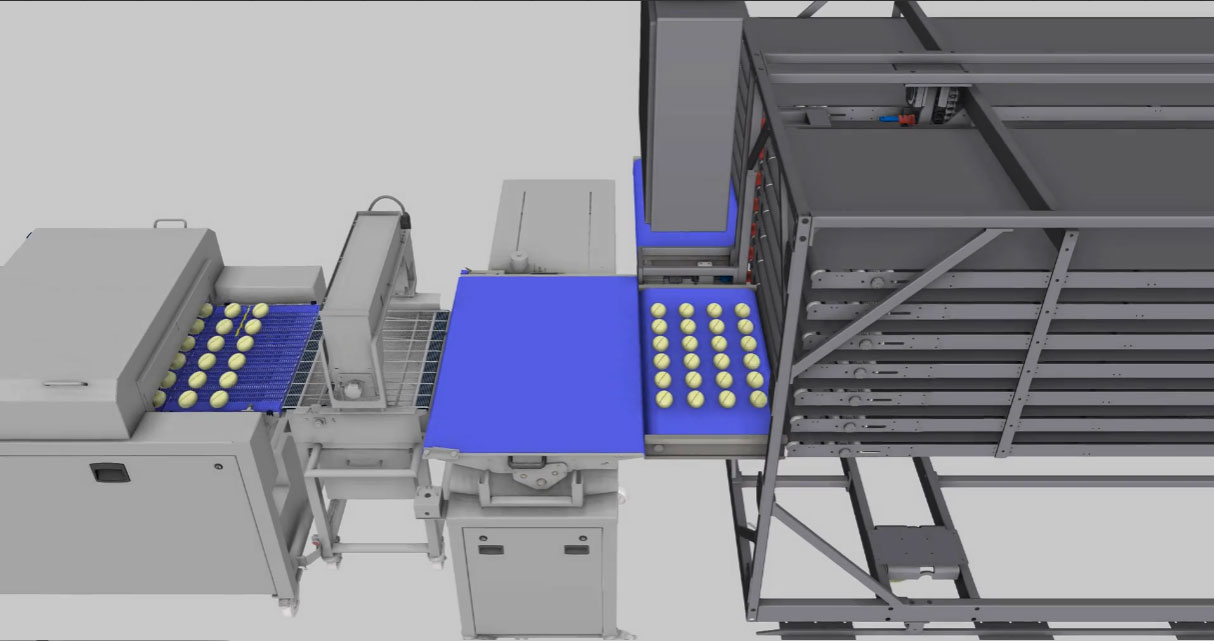

The WP Riehle Eco-Freezer combines a large freezing area in a small space. Thanks to its design, it offers 54 m² of freezing area on a footprint of only approx. 12 m². The dough pieces are transferred to the wire mesh belts in the freezer using optional feed systems. The entire mechanism is located in the Eco-Freezer during each work step, so that only the dough pieces, but not the mechanism, need to be cooled down. This results in significant energy savings compared to a rack freezer. Immersing of the freezer mechanism in a cooling trough ensures very short freezing times with very low energy consumption.

Various parameters for freezing time can be entered via the Beckhoff touch panel control with the remote maintenance option. Thanks to its modular design, the freezer can be easily modified in width and length. The available feeding systems carry out the transfer of products from the upstream production systems into the Eco-Freezer. Once freezing is completed, the frozen dough pieces are automatically discharged and can be transferred to a packaging system.

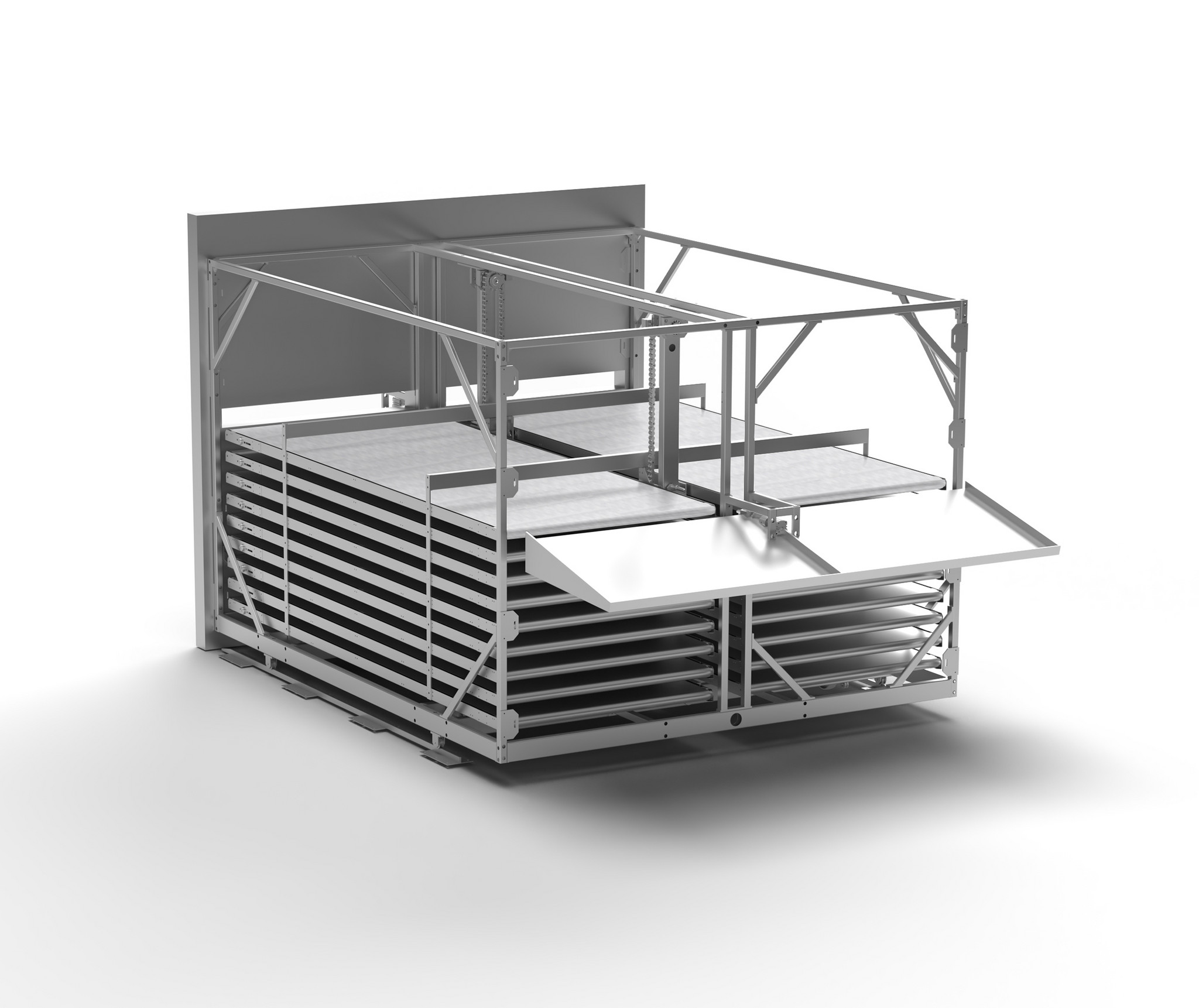

| 1.1 | Conveyor belts |

| 1.2 | Motor with coupling for belt drive |

| 2 | Motor lifting unit |

| 3 | Lifting unit for two lifting trucks |

| 4 | Self-supporting frame |

| 5 | Control cabinet with Beckhoff touch panel control - with multi-level operator menu Operator-Master-Service - internet-capable for remote maintenance - can also be controlled via upstream WP Riehle ComJet with central control system - Supply and discharge systems can be integrated |

| 6 | Fixing frame for mounting of the insulation |

| Useful freezing area: | 21-69 m² or larger |

| Dimensions of the frozen products: | hight max. 60 mm, Diameter min. 10 mm |

| Freezing time: | Adjustable settings for processing time |

| Temperature range: | -40°C to +40°C |

| Connections (without cooling): | 16 A/400 V, 6 bar compressed air, W-LAN/network connection for remote maintenance |

High-quality freezer for the best results

The storable parameters for different freezing time and the automatic discharge of the dough pieces after freezing, which can further be transferred directly to a packaging system, ensure consistent quality of the dough pieces.

- Large freezing area in a small space

- Low energy requirement (significant energy savings compared to rack freezers):

- Entire mechanism inside the freezer, no additional cooling of the mechanism necessary

- Remote maintenance possible thanks to touch panel control

- Storage of different freezing parameters

- Modular design with the option of variable width and length adjustment

- Automatic discharge of the dough pieces after freezing is completed

Example:

1-row from approx. 1,900 pretzels / hour

2-row from approx. 3,800 pretzels / hour

up to your desired size

Options

- Feeding systems

- Variable width and length thanks to modular design

Simulation of the Eco-Froster (without case)

Simulation of the Eco-Froster (withour case)

For all dough pieces

The freezer can be optimised for different dough pieces.

Artisan baguettes

Bauernbrot

Holzofenbrot

Kaiser rolls

Pretzel

Hamburger buns

Hot Dog buns

Grain breads

Unsere Vertriebsmitarbeiter beantworten gerne Ihre Fragen zum Produkt.

![[Translate to Englisch:] Aufbau-Schaubild des Eco-Frosters 4200 [Translate to Englisch:] Aufbau-Schaubild des Eco-Frosters 4200](/fileadmin/_processed_/3/f/csm_schaubild-eco-froster_df6b0d2e74.jpg)