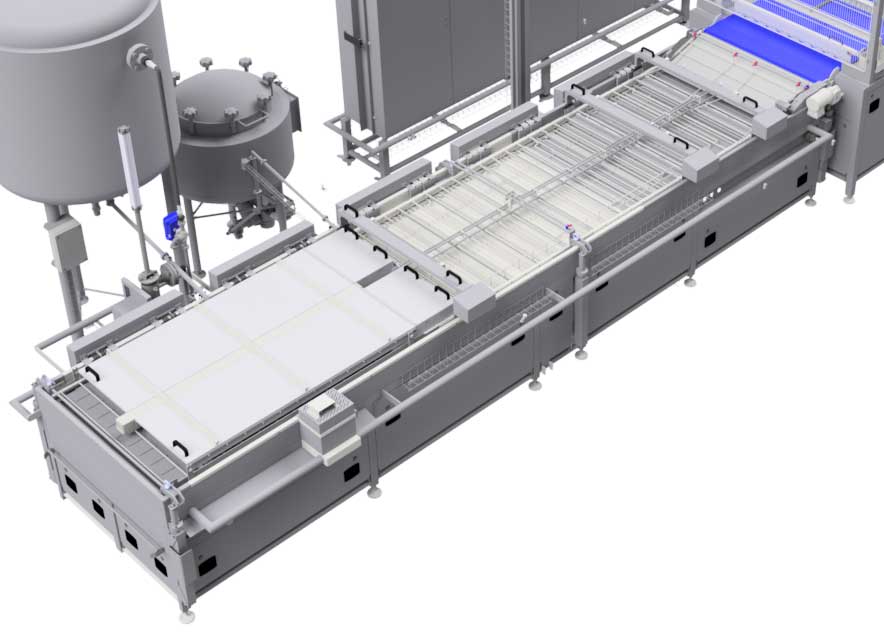

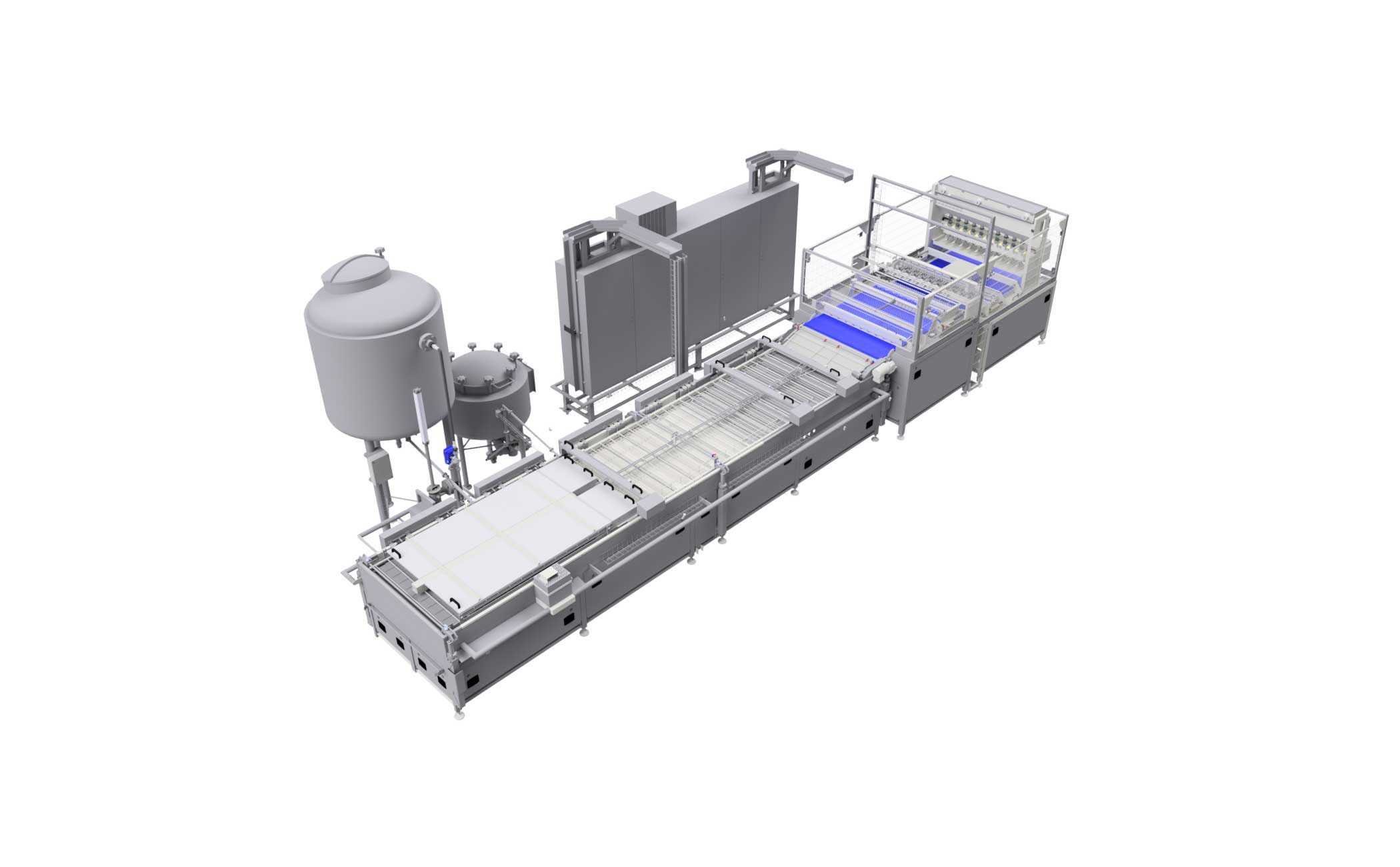

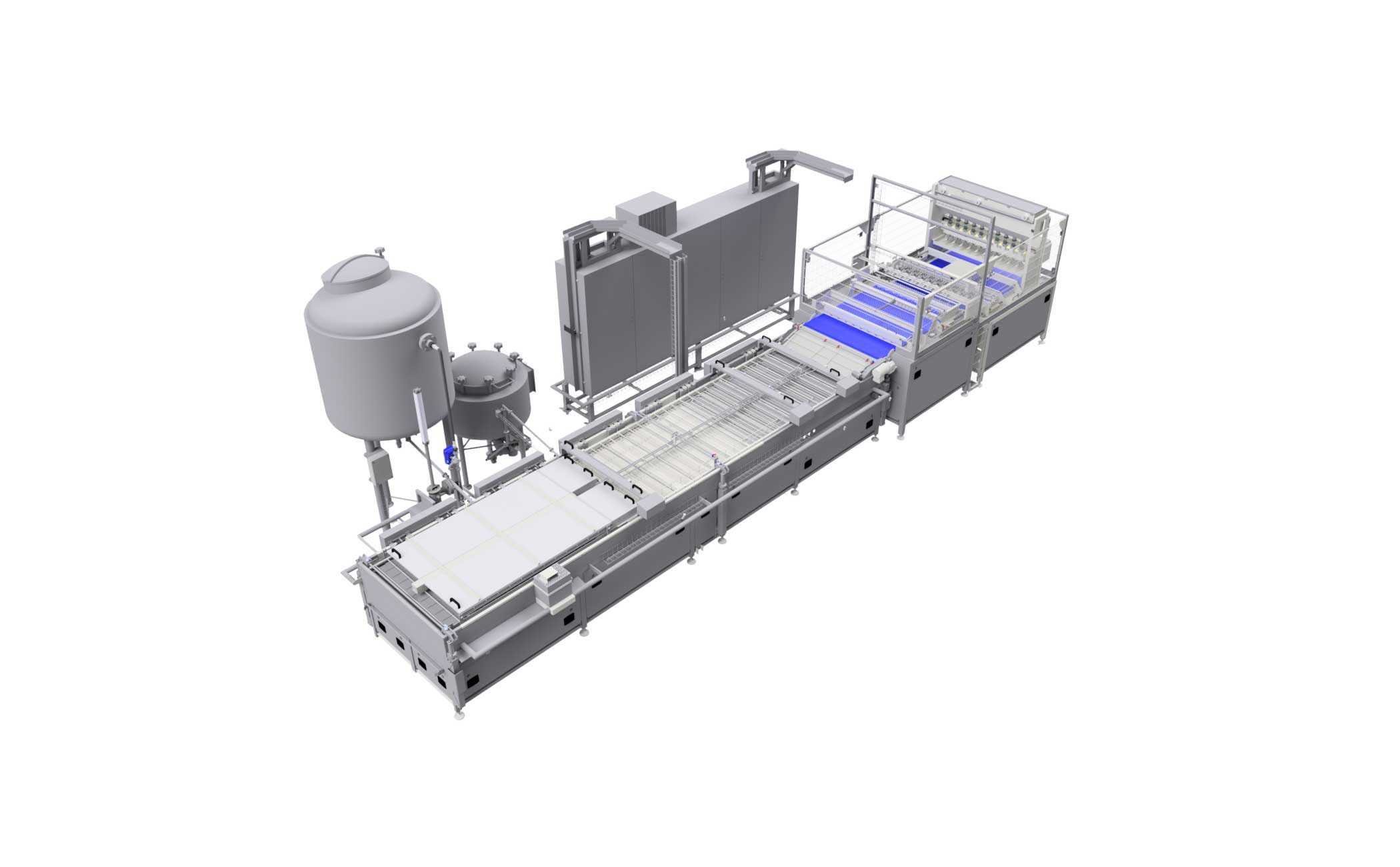

Industrial continuous frying system

IDA 1100-40

- Up to 4,000 Berliner donuts / 8,000 donuts per hour

- high production efficiency

- Products with artisan quality

- fully automatable

‘Berliner’ donuts and curd cheese dumplings in best handicraft quality

The proven Riehle steam lid also ensures excellent volume output of donuts/pastries in the large IDA systems. The intelligent temperature control reduces fat absorption to a minimum.

Details of the continuous frying system IDA 1100-40:

Input systems

Depending on the products, modular input systems for IDA are available:

Cloth feeding table (if necessary with row doubling), automatic loader, system trolleys with transfer / distribution unit, automatic 2-fold dosing for curd cheese dumplings, crullers, cake-donuts, and much more.

Intuitive touch control

- Resistant to grease and dirt

- All connected additional devices are controlled via the baking programmes

- Turning process controlled by servomotors

- Can be networked with LAN or WLAN

- Your machine can be maintained remotely, minimising downtime and costs a technician on-site is not always needed

- Technical support can be provided remotely, so experts can access and assist with real-time troubleshooting and resolution via the internet to support your company technician

- Important data and information of your machine can be accessed remotely, allowing you to monitor the status of your machine and the production data anywhere, anytime

- Touch control panel provides detailed production statistics and reports that offer insights into performance metrics, efficiency and utilisation

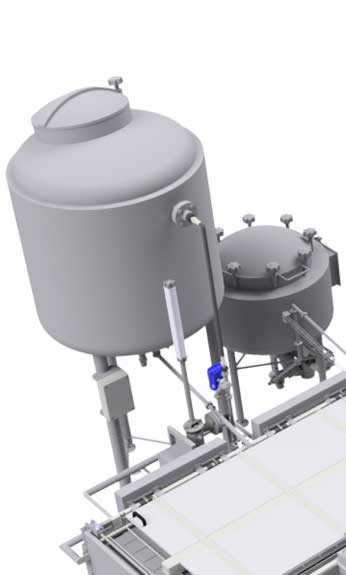

Fat / oil management system

- Automatic level control via heated refill cloth

- Heated drain / cleaning cloth

- Continuous fat / oil filtration with stainless steel permanent filter element

- Control and programming of all connected system components

Decoration

10-fold filling of Berliners (laterally) and donuts (from above), sugaring, powdering, return conveyor, sugar turntable,

transfer belts to freezers, bouncing belts for tray storage, robot automation

FRYER

- 3 servomotor controlled twists, can be individually switched off and recessed in the tray

- Hydraulic lifting unit for transport use and heating, hence tray accessible from all sides

- Separate heating zones, controlled independently of one another for constant temperature and lower grease absorption

Performance, maximum benefit and modular options

For large production with high demands

- Feeding:

- the IDA can be configured with one or more different feeding systems

- Grease tank:

- the IDA has a storage tank with preheating

- Cleaning:

- easy cleaning of the grease tray thanks to tool-free removal of the transport unit and support by hydraulic lifting unit

- Control system:

- intuitive operation via robust touch glass display

Per hour

up to 4,000 Berliners

up to 8,000 Donuts

Options

- Cloth feeding table

- Loading robot with proofing material unwinding system

- automatic dispenser

- automatic donut filling station

- Sugaring module

- Eco-Froster

For all types of donuts

The IDA can be customised to meet the requirements of your products

Ball donuts

Donuts

Curd balls

Fritters

Unsere Vertriebsmitarbeiter beantworten gerne Ihre Fragen zum Produkt.