Deep fryer

Linie 2000E

- Up to 50% energy saving

- Lower fat absorption due to precise temperature control

- Only 40 liters fat volume

Energy saving and ergonomic:

The automatic deep fryer for the highest demands

With the Linie 2000 E (single units, VARIO or TRIO), fully automatic baking is possible thanks to the programmable baking processes and the automatic turns. The volume steam lid remains closed until each turn, thus ensuring a larger volume of baked goods at the same weight. The baking process is automatically terminated when the turning basket is moved out. This ensures your product quality, even if something comes up.

Energy saving like never before

Sustainability of resources in perfection

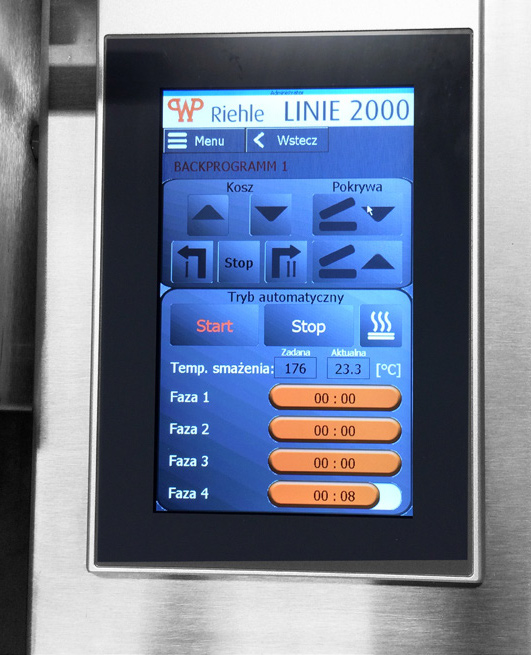

Controlled fat baking with touch control

- Resistant to grease and dirt, also works with greased display

- All connected additional devices, such as filling, sugaring, etc., are controlled via the baking programmes

- Turning process controlled by servomotors

- Touch control panel provides detailed production statistics and reports that offer insights into performance metrics, effi ciency and utilisation

OPTIONALLY:

- Can be networked with LAN or WLAN

- Your machine can be maintained remotely, minimising downtime and costs a technician on-site is not always needed

- Technical support can be provided remotely, so experts can access and assist with real-time troubleshooting and resolution via the internet to support your company technician

- Important data and information of your machine can be accessed remotely, allowing you to monitor the status of your machine and the production data anywhere, anytime

The LINIE 2000 E offers numerous advantages

- Tightly closing WP RIEHLE steam lid for larger baking volume on the same given weight

- Longer fat life due to constant temperature

- Lowest energy consumption and constant temperature due to direct heating in oil

- Low energy consumption due to oil tub insulation

- Various system configurations available, such as: Single unit, Vario station, Trio station, etc.

- Computer control with individually programmable baking programmes for consistent quality

- All connected system parts are controlled via the baking programme. When the baking programme is changed, for example, the filling is also changed automatically.

- Flexibility to optimise production processes

- Mobile with castors with brakes

- High energy saving

- Resource efficient production (electricity, fat, personnel, space)

Accessories

- Mobile trolley with oil drain filter tank, fat melting unit, heater and backwash pump.

- Turning baskets and dumping trays (each with 4 or 6 rows)

- Trolleys for proofing chamber (8, 9, 10, 16, 18 and 20 shelves)

- Wide range of accessories, such as: automatic filling, sugaring, powdering, sugar turntable, dosing devices for French crullers, donuts and cottage cheese bally

Performance, maximum benefit and modular options

Many equipment options that make your everyday work easier and increase the quality of your products. The proven baking result of the 2000 A line has been retained despite enormous energy savings.

- Sustainability facts: Energy

- approx. 50% energy saving while heating

- approx. 25% energy saving while baking

- approx. 25% energy saving while idling

- Sustainability facts: Material

- Reduction of the fat volume from 49 litres to 40 litres

- Reduction of fat absorption through digital heating control

- Pulsed heating against fat burning ensures longer fat life

- Sustainability facts: Personnel

- Halving of the waiting time during heating, thus higher machine availability

- Ergonomic working height: 91,5 cm

- The use of Vario and Trio stations ensures a significant shortening of work routes and waiting times

Number of pieces:

For up to 60 Berliners (single unit) / 120 Berliners (vario station) / 180 Berliners (trio station) per baking process

600 / 1,200 / 1,800 Berliners per hour (with 6 minutes baking time)

Energy saving compared to the predecessor model:

Up to 25% energy saving during baking & idling phases

Up to 50% energy saving when heating up

Heating up twice as fast

Options

- Turning baskets and dumping trays (each 4- and 6-row)

- Trolleys for proofi ng chamber (16, 18 and 20 shelves)

- Available as vario station, two units connected with a common centre table

- Available as trio station, three units connected with common centre tables

- Mobile fat cleaner with oil drain filter tank, backwash pump and fat melting heater

- Exhaust bonnet

- Automatically filling and sugaring

Für alle Siedegebäcke

The automated processes ensure simpler production and consistent product quality. The touch panel control enables intuitive operation.

Berliner

Donut

Cake Donuts

Quarkbällchen

Spritzkuchen

Unsere Vertriebsmitarbeiter beantworten gerne Ihre Fragen zum Produkt.