Fried products

DLA 150-600

The automatic continuous open kettle fryers for submerged and floating deep-frying of all kinds of products

- more even + faster frying

- low fat absorption

- energy saving

Continuous fryer DLA 150-600

The optimal solution for better products with less effort

For the continuous open kettle fryers we offer different possibilities of product infeed. You can choose either automatic dosing, input via a forming machine or manual input and configure the device accordingly.

Performance, maximum benefit and modular options

With the comprehensive configuration options and sizes,

you too will find your optimal solution!

- Product quality:

- Reduction of deep-frying time with submerged frying

- less fat absorption thanks to digital heating control

- reproducible product quality through 7 adjustable baking programs

- Technical specifications:

- Glass display control with 7 storable baking programs

- infinitely variable adjustment of the throughput speed, clocked or continuous operation possible

- Hygiene:

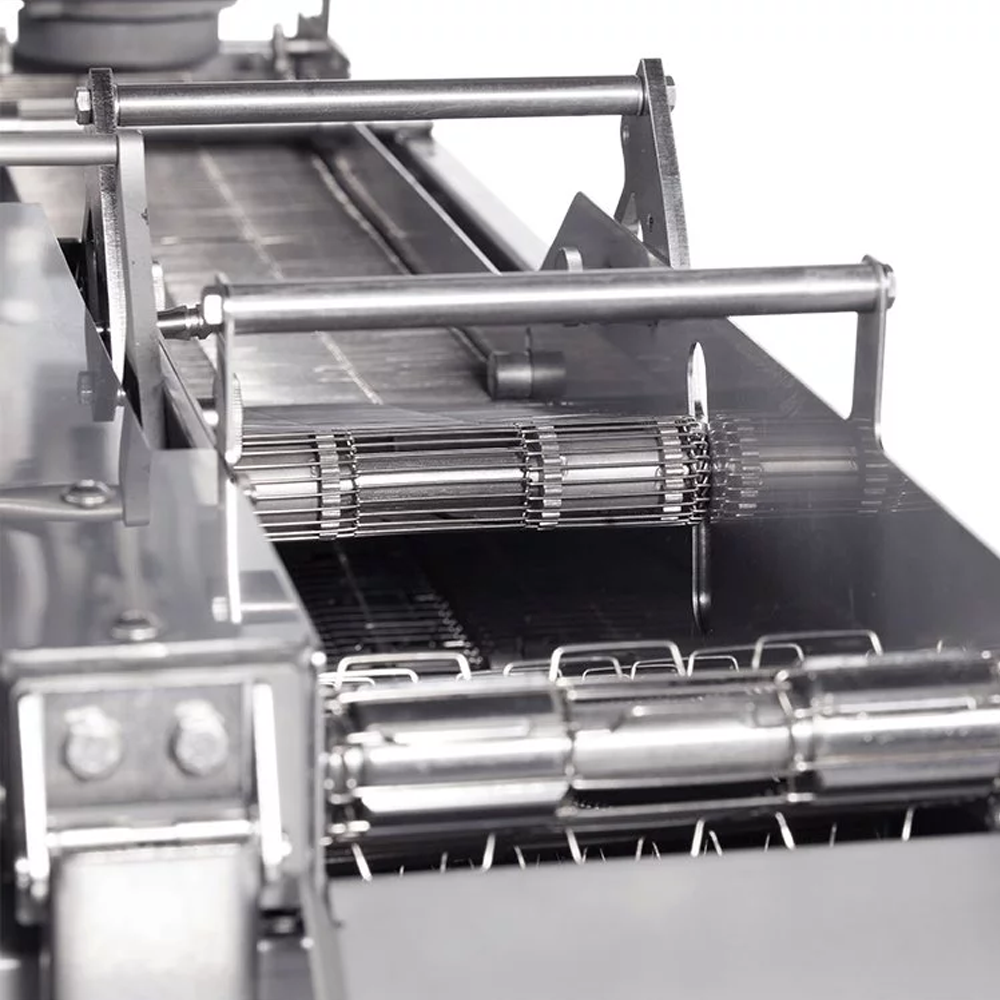

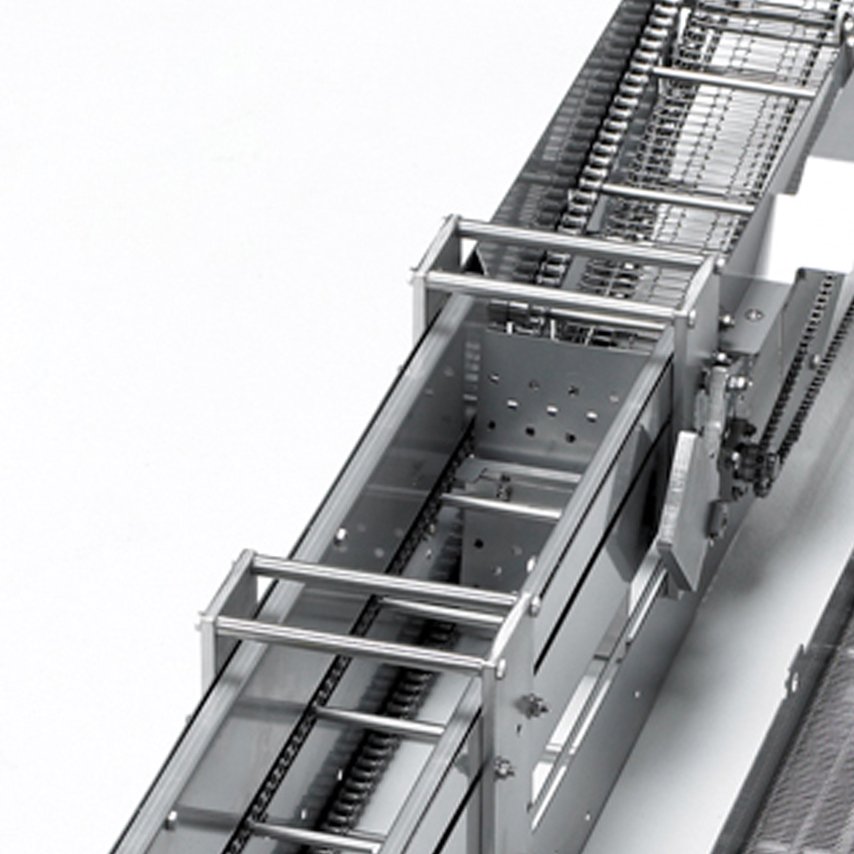

- Tool-free removal of the transport unit makes cleaning easy

- the DLA 600 is optionally available with a hydraulic lifting unit for easy cleaning

Per baking process

The capacity per hour depends on the product and plant size as well as the corresponding frying time

Looking for a different product?

World of products

Options

- automatic dosage

- Turning insert

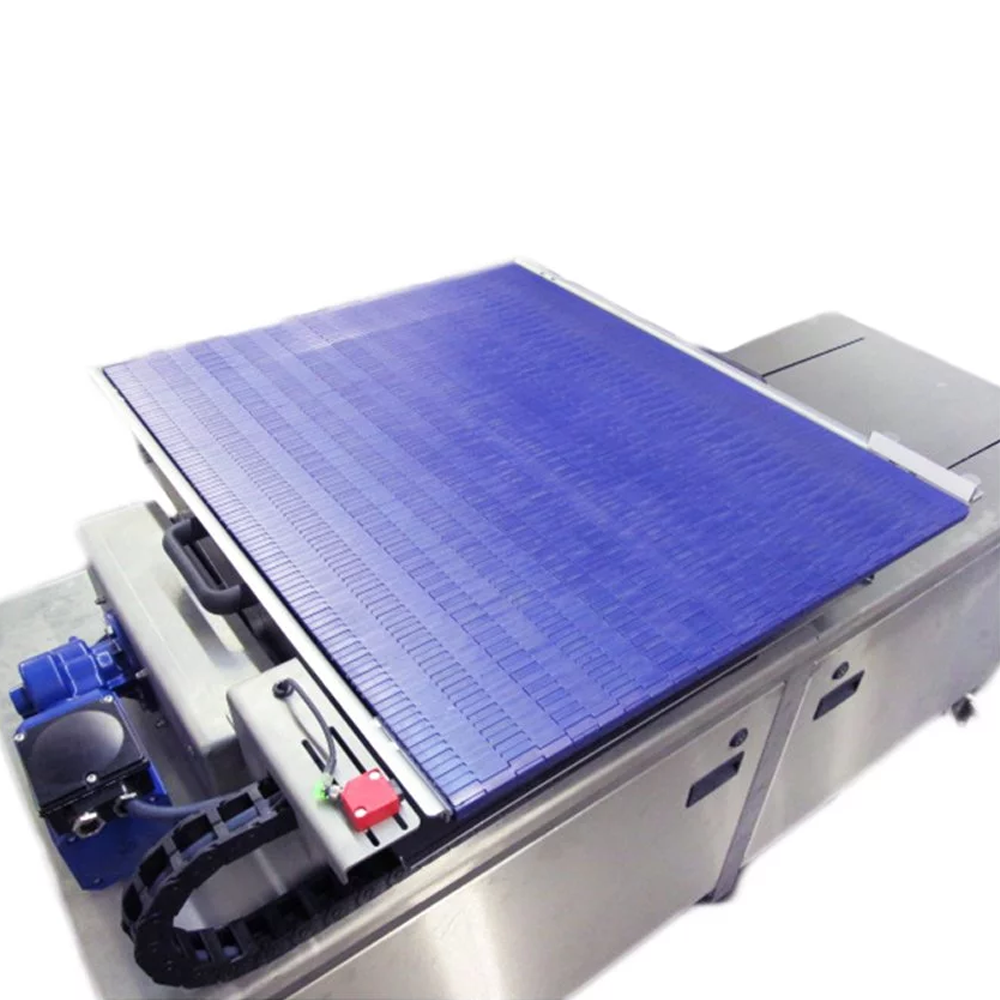

- Cross distribution belt

- Sugar turntable and other storage possibilities

- Cooling belts

- the DLA 600 is available with hydraulic lifting unit for transport unit and heating

For all types of donuts

Simple and efficient operation from small to large quantities

Berliner

Donut

Cake Donuts

Quarkbällchen

Spritzkuchen

Production of cottage cheese balls with a DLA

WP Riehle DLA 150-2

Baking trial at Jung Zeelandia with spritz cakes, doughnuts and more

WP Riehle DLA 150

Production of filled cottage cheese balls with a DLA

WP Riehle DLA 300-2

WP Riehle

+49 7363 95390-0

Unsere Vertriebsmitarbeiter beantworten gerne Ihre Fragen zum Produkt.

Looking for a different product?

World of products